Shortages, price hikes: change of raw materials? Adaptation of recipes? Updating of product sheets? New data to be provided for eco-design?... All this in a hurry? How to cope?

In the unprecedented and unstable context we are living through, lack of resources and environmental urgency, adapting quickly and accurately has become vital for all agri-food companies.

Teams are forced to constantly adapt recipes and products. Modifying or updating a product or a range of products takes at least 6 months with the most common working methods and organisation.

Today, relying on concrete, proven software tools adapted to the specific needs of the food industry accelerates the modification, innovation and eco-design processes and reduces the time to market.

Adapting effectively with proven and practical digital tools for the food industry

Example of sunflower: which products are affected by the shortage? Do you plan to substitute it with a soya, peanut or other equivalent? What is the impact on recipe costs? How much time is spent reformulating and updating product sheets to be sent to customers? Even if certain rules have been relaxed, it remains that certain information is still mandatory.

With Keendoo software solutions, the products concerned are identified in one click. Replace a raw material by another one? Substitute all affected recipes at once. Price increase? Recalculate massively the products' PRIs. Optimise, reformulate products? Simulate trials in parallel with live visualisation of the impact of modifications on the PRI, labelling mentions such as Nutri-score®: trials saved. Update product sheets? Generate the new version, in bulk or by product reference. The updated, reliable product data can then be transmitted with confidence to the open source database of information on modified products made available to consumers by the DGCCRF and to the GDSN electronic catalogues.

Collaboration: the key to the efficiency of Kenedoo tools

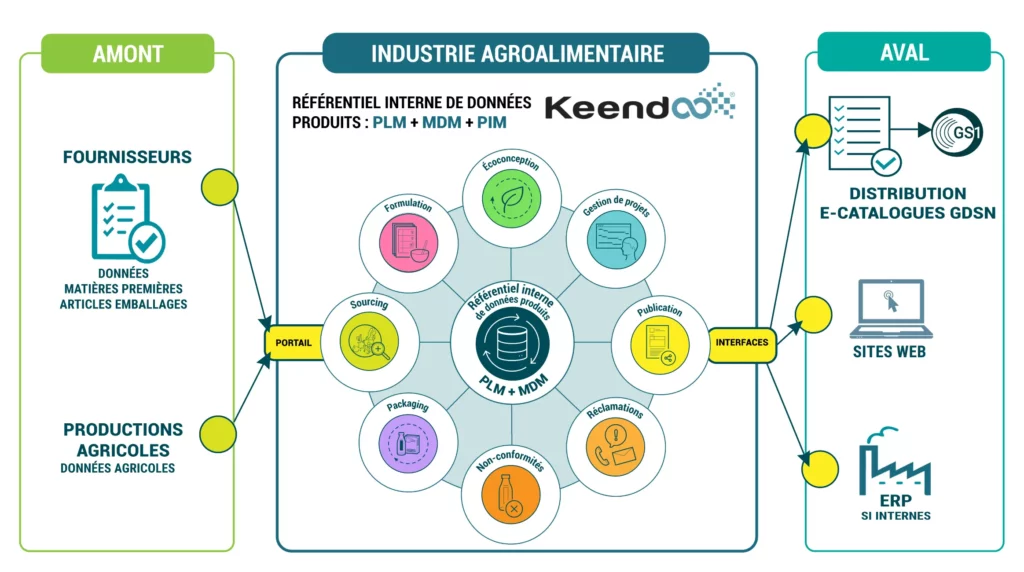

The key to the effectiveness of such tools is collaboration, both internally and externally with suppliers. Innovations, developments, modifications, practically all the company's departments contribute: purchasing, R&D, management control, quality, marketing, packaging, production, sales, etc. What a lot of time is saved by working together on an internal product database that each person enriches within his or her own area of expertise: the data generated and made reliable by one person is immediately available to the others. Combined with automated processes, validation circuits are secured and projects are structured. This is what Keendoo offers: an internal product data repository for unified, versioned, reliable and up-to-date data.

Results: fluidity, efficiency, improved time to market, reliability and quality of data provided to the GDSN platform.

Rely on structured and consolidated data to accelerate eco-design

Other constraints weighing on companies: environmental and climate issues. In several forms: the new regulations (Agec, Climate & Resilience laws), the bonus/malus of the eco-packaging contribution (Citéo, etc.), and the soon-to-be mandatory environmental labelling, require all products to be reviewed. Innovation now goes hand in hand with eco-design.

Ecodesign is based on a standardised approach in 3 main stages:

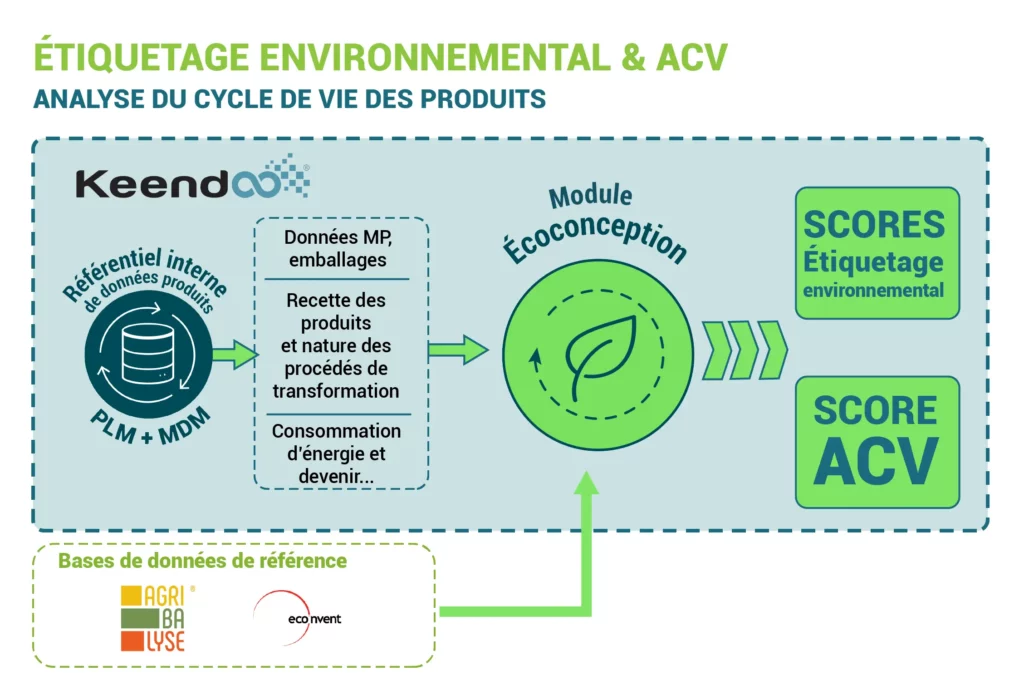

♻️ The first step is to carry out a product life cycle analysis, or LCA, to measure its environmental impact. This standardised, multi-criteria, multi-stage analysis is based on a large amount of data, often scattered and duplicated in different departments of the company. Collecting and consolidating this data takes an average of 5 days for a single product for a specialised firm. When the data is already structured and reliable in the Keendoo product repository, it is immediately available to calculate the LCA score of the products.

♻️ Second step: identify action levers with eco-design experts, as our partner O2M Conseil does. New sources of raw materials, new formulas, new packaging, new production methods...

♻️ Third step: test the action levers.What impact on the LCA score? What impact on the PRI? On labelling? All this with complicated calculations in spreadsheets? This is where Keendoo proposes the new Eco-design module. Linked to the product repository, it uses this data for calculations: environmental display score, LCA scores, the impact of different levers on the environmental footprint of products.

Consolidate product data internally to improve responsiveness

Increasingly, product data is the foundation of the information system, as it concerns practically all the company's departments. How can we ensure the digital transformation of the company if this foundation is not solid? Today, the main challenges are adapting recipes and environmental design. Tomorrow there may be others, but always around product data.